Table of Contents

In the world of large-scale constructions, there is often a significant disconnect between a beautiful architectural rendering and the actual physical components that arrive on a flatbed truck.

You might have the most sophisticated structural plans. Still, when it comes time to fabricate a specific precast wall panel or a complex steel connection, those designs lack the granular detail required for manufacturing.

This is where the question of “what is a shop drawing” becomes central to your project’s success.

What is a Shop Drawing in Construction?

A shop drawing is a detailed fabrication document that provides manufacturers and installers with the exact information needed to produce and erect structural components. It includes dimensions, material specifications, connection details, reinforcement layouts, and installation sequences.

In simpler terms, an architectural drawing shows what the building should look like. A structural drawing ensures it won’t fall. But a shop drawing tells the factory exactly how to make each component and tells the site crew exactly how to install it.

Shop drawings include:

- Precise dimensions with tolerances

- Material grades and specifications

- Reinforcement details, including bar sizes, spacing, and cover

- Connection specifications with bolt sizes, weld types, and plate thicknesses

- Embedment locations for inserts, anchors, and MEP sleeves

- Erection marks and installation sequences

- Lifting and handling details

- Coordination with MEP systems

In precast construction, shop drawings are particularly critical. Each component is cast in a controlled factory environment based on these documents. Errors discovered after fabrication result in rejected pieces, project delays, and substantial cost increases.

Need expert shop drawing support?

Key Components of Professional Precast Shop Drawings

To understand what is a shop drawing in construction, one must look at the specific data points required for successful fabrication. A high-quality precast shop drawing package is not merely a visual aid; it is a technical manual containing several critical layers of information.

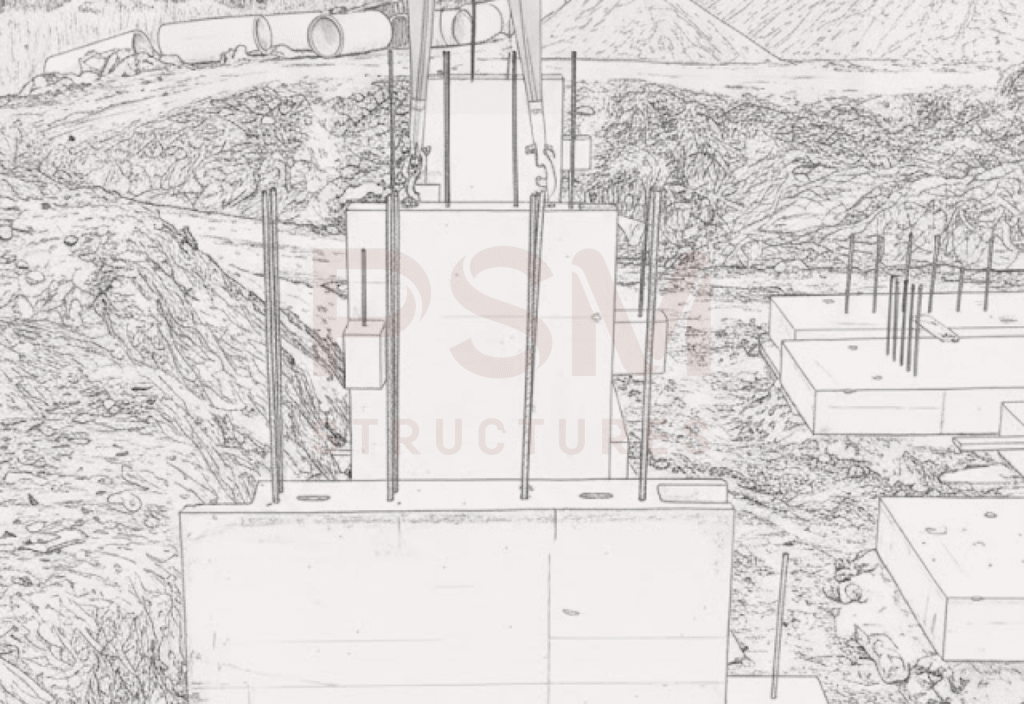

1. Element Marking and Erection Plans

Every individual component is assigned a unique identification number. These marks are essential for tracking the piece from the casting yard to the transport trailer and, finally, to its specific coordinates on the site. This ensures a logical erection sequence and prevents logistical bottlenecks.

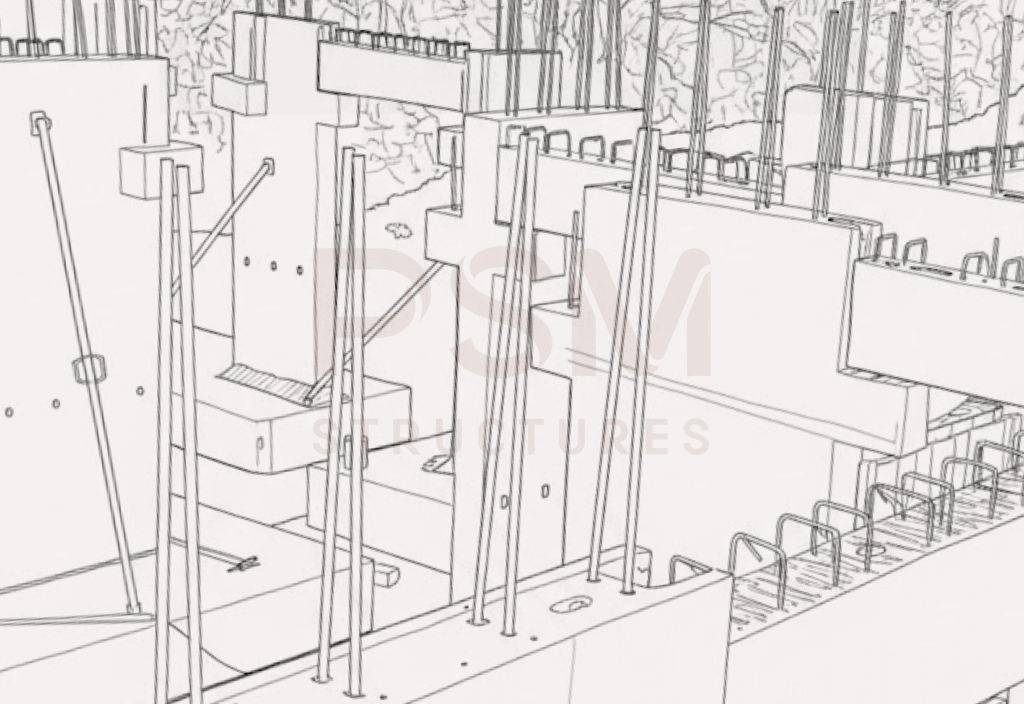

2. Precise Reinforcement Detailing

The structural integrity of precast concrete depends entirely on its internal steel. Precast shop drawing services provide exhaustive details on bar diameters, spacing, lap lengths, hooks, and bends. At PSM Structures, these are often accompanied by comprehensive Bar Bending Schedules (BBS) to streamline the steel cutting and bending process.

3. Integrated Connection Details

The joints between precast elements are the most vulnerable points in a structure. Shop drawings must clearly illustrate weld plates, grouted sleeves, dowels, bolted connections, and anchoring systems. These details ensure that the load path is maintained across the entire building assembly.

4. Safety-Critical Lifting and Handling Details

Properly engineered lifting point locations are vital for both the structural safety of the element and the personnel on-site. The National Institute for Occupational Safety and Health (NIOSH) emphasises that improper lifting practices contribute significantly to structural failures and site accidents. Our drawings specify the exact hardware and rig points needed to handle heavy precast loads safely.

5. Dimensional Tolerance Specifications

Shop drawings define permissible dimensional variations. By establishing these tolerances early, we ensure that elements can be installed and aligned on-site without clashing with other structural members.

In precast engineering, you only get one chance to get it right. Once the concrete is poured, the cost of error increases by a factor of ten. Shop drawings act as our final simulation where we catch clashes between reinforcement, MEP inserts, and lifting hardware before they become expensive site problems

Parv Modh

Difference Between Design Drawings and Shop Drawings

What this really means is that a shop drawing is a specialised translation of the architect’s intent into the fabricator’s language. An architectural plan might indicate a precast concrete column of specific dimensions, but a precast shop drawing will specify the exact placement of reinforcing bars, the type of concrete mix, the location of lifting inserts, and the precise dimensions down to the millimetre.

According to data from the Project Management Institute (PMI), documentation errors are a primary driver of project delays and budget overruns. Shop drawings serve as a communication protocol that ensures the factory team understands the engineer’s requirements. Without this level of detail, the risk of a component arriving on-site only to find it does not fit the surrounding structure increases significantly.

The Critical Role of Precast Shop Drawings

In the precast construction industry, accuracy is the primary structural requirement. Once a concrete element is cast, modification is difficult and expensive. This makes precast shop drawings the technical foundation of the assembly process.

1. Verification of Manufacturing Tolerances

Every element must account for material behaviour such as shrinkage and thermal expansion. Shop drawings calculate these variables to ensure that multiple precast panels align perfectly within the structural frame during erection.

2. Integration of MEP Embeds

Modern infrastructure requires mechanical, electrical, and plumbing (MEP) systems to be integrated directly into structural members. Precast shop drawing services ensure that conduits, sleeves, and junction boxes are positioned correctly before the concrete is poured, preventing the need for risky post-cast drilling.

3. Systematic Installation Instructions

What is a shop drawing in construction if not a manual for the field crew? These drawings include specific “erection marks” that guide the assembly sequence, ensuring that the crane operator and site engineers know the exact location and orientation of every piece.

Looking for execution-ready designs?

Minimise your on-site risks with our expert detailing services.

The Technical Shop Drawing Approval Cycle

The development of shop drawings is a collaborative process involving multiple stakeholders. Once a specialist firm prepares the draft, it follows a standardised review path:

- Preparation: Engineers use BIM software or CAD to generate the detailed drawing based on contract documents.

- Internal Validation: Senior structural engineers check the drawing against local building codes and load requirements.

- Consultant Review: The drawing is submitted to the Architect and Structural Engineer of Record.

- Final Status: The drawing is returned with a status of “Approved,” “Approved as Noted,” or “Revise and Resubmit.”

Regulatory Compliance and Code Requirements

Shop drawings must satisfy building code requirements applicable to the project location. In India, this includes compliance with IS 456 for concrete design, IS 1893 for seismic requirements, and IS 800 for structural steel connections.

For projects following international codes, ACI 318 governs concrete design and detailing. AISC standards apply to steel connections. Regional amendments and local authority requirements may impose additional constraints.

Precast shop drawings specifically must address:

- Load transfer mechanisms at connections

- Seismic force resistance and ductility requirements

- Durability provisions including concrete cover and crack control

- Fire resistance ratings where applicable

- Diaphragm action and lateral load distribution

Professional engineering stamps and approvals are required in most jurisdictions. Shop drawings prepared by fabricators typically require review and approval by the engineer of record before fabrication proceeds.

Get accurate, code-compliant shop drawings for your precast project.

Engineering Precision for Modern Projects

Understanding what is a shop drawing is vital for any stakeholder in the construction industry. These documents are the definitive guide for how a building is physically assembled. They protect the structural integrity of the project and ensure that the developer’s budget is not consumed by preventable errors.

In precast construction, shop drawing quality is non-negotiable. The controlled manufacturing environment and rigid nature of precast components mean that errors are expensive and time-consuming to correct. Proper shop drawings prevent these issues through thorough detailing, coordination, and review.

At PSM Structures, we specialise in providing high-fidelity structural solutions. With over 7 years of experience and 20,000 sq m of precast projects designed, we bring technical rigour to every project. Whether you are an EPC firm or a precast manufacturer, our precast shop drawing services are designed to ensure your project is completed faster and more safely.

Explore precast design and shop drawing services at PSM Structures.

FAQs About Shop Drawing

A shop drawing provides detailed fabrication and installation instructions for manufacturing and erecting structural components. It specifies exact dimensions, materials, reinforcement, connections, and installation procedures that translate design intent into buildable elements.

Shop drawings are prepared by contractors, fabricators, or specialized structural engineering consultants. The party responsible for fabrication typically prepares the drawings, which must then be reviewed and approved by the project's design team before manufacturing begins.

Precast components are manufactured based on shop drawings in a factory environment. Errors result in rejected pieces, schedule delays, and significant replacement costs. Accurate shop drawings ensure components are fabricated correctly and fit together properly during site installation.

The approval process typically requires 2-4 weeks for straightforward projects and 4-6 weeks for complex structures. Multiple review cycles may be needed as structural engineers, architects, and contractors provide comments and require revisions.

Yes. One of the primary functions of a shop drawing is to provide an accurate bill of materials for procurement and fabrication.